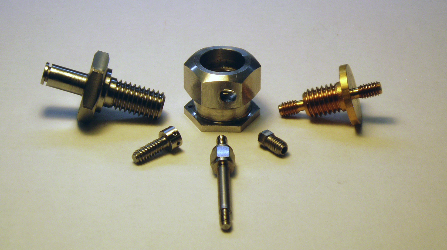

Welcome to Vaughan Jones Socket Screws Limited. 100% manufacturer of special screws and turned parts.

We hold approval to ISO:9001 2015 as well as Ministry of Defence AQAP4.

News

March 2021

We are celebrating our 60th anniversary this year! Originally founded in Scotland in 1961, please visit our company profile for more information. A big thank you to all of our customers and suppliers, we look forward to the future and another 60 years!

September 2020

We have taken delivery of a brand new machine. The new model is a STAR Micronics SB-20R type G.

The addition of this latest machine allows us to deliver the highest levels of product and service quality that our customers have come to expect.

This is our seventh CNC sliding head machine, and our skilled operators are already putting the additional capacity to good use.

February 2020

Our new factory is fully up and running.

The move from our old premises based near Wetherby is now complete.

The full address is as follows:

Vaughan Jones Socket Screws Ltd.

Precision House

Ring Road, Seacroft

Leeds

LS14 1NH

December 2019

We are moving!

Vaughan Jones moved to Thorp Arch near Wetherby in 1972, and after 47 years, we will be relocating to a new site in Seacroft Leeds.

Managing Director Jeremy Hornby said: "The new building will reflect a better impression on our customers, to match the high quality of the products we manufacture, and have become known for in the 58 years we have been making special fasteners and turned parts."

The company is set to move on the 24th January 2020 and we will be updating our information and contact details in due course.

May 2018

Vaughan Jones has achieved approval to the 2015 revision of ISO 9001. This helps to assure new and existing customers that we are committed to supplying high quality product whilst achieving continual improvement and growth as a business.

See above to view or download our approval certificate.

June 2014

We have installed yet another new Star machine, in the form of a new SR20J With 4 meter bar feeder which arrived this month and is fully installed.

This machine replaces the very first machine purchased in 2001, which was part exchanged.

The new machine is more capable and has faster rapids than the original machine, also being new is more precise.

June 2011

Celebrating 50 Years in Business!

June 1961 - 2011

WE HAVE INSTALLED A FURTHER STAR SR 10 J MACHINE.

Due to demand from our customers for the smaller sizes we purchased a new Star SR10J from Star Micronics.

Having purchased the first of this type of machine, off the stand at the Mach exhibition at the N.E.C in 2006, the company decided to double up with this new very quick machine.

December 2007

A brand new Citizen L20 VIII, 8 axis CNC lathe was installed this month. This machine compliments the exsisting Star machines.

The machine is fitted with high pressure/chilled coolant for assistance with swarf control particularly when machining difficult material

June 2006

We are proud to announce the purchase of a brand new Star SR10 from the Star Micronics Stand at MACH 2006.

The machine has a maximum bar capacity of 10mm, and has 35 metre rapids to ensure tools get to the cutting positions as quickly as possible. This new purchase compliments our exsisting 2- 20mm diameter machines and the 32mm capacity machine.

April 2005

Our new state-of-the-art Swiss-type sliding head automatic CNC lathe is now fully operational. The bar-feed has been laser-aligned, the necessary filters installed, the viewing panel replaced in order to cope with the high pressure coolant system installed, and all the necessary tooling has been installed and tested. Vaughan Jones' engineers have also completed their extensive training on the new machine, and the first turned parts are due to be produced on the machine by April 15th.

March 2005

Our new swiss-type lathe has been delivered and will be up and running in April. Managing Director Jeremy Hornby said, “The purchase of this machine is to help Vaughan Jones build on its long history of producing quality specialised fasteners, quickly and to the high standards our customers expect. With the new machine comes the ability to manufacture new turned parts, which will benefit many of our existing customers, as well as helping us to attract new ones.”

The new machine is able to produce even more specialist parts Parts with internal threads, off-centre hole drilling, parts with angled holes, and parts that require drilling on the end face are now possible. Several features on the new machine, such as offset tool-setting and balanced turning, will enable the company to increase its capability whilst maintaining its reputation for quality.

January 2005

We have ordered our 3rd New machine from Star Micronics UK for delivery in March 2005. The 32mm capacity machine increases the size we can handle on these multi-function mill/turn machines with the new machine having a capabilty of 80 tools for one hit manufacturing.The new machine has been ordered with long parts facility, magazine bar feeder, swarf conveyor and high pressure coolant, all to assist with production on 24/7 basis, some lights out. This machine builds on our earlier heavy investment in state of the art machinery to service our customers in the manner they are becoming accustomed to.

September 2004

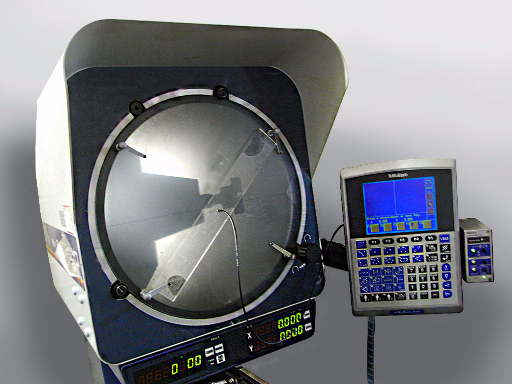

We have purchased a brand new profile projector from Mitutoyo, complete with QM Data and optieye edge sensor. This is a state of the art machine for use by setters and our inspection department.